The content of the article

Foam is used during the installation of windows and window sills, doors, plumbing fixtures and others; it is widely used as a heater - it tightly seals all the cracks; It is indispensable for the production of sandwich panels. Foam can become not just a lifesaver, which will eliminate any shortcomings and flaws made during construction, but also an indispensable assistant at all stages of work. And since its use without auxiliary means is impossible, it is necessary to be able to handle a special gun.

Types of polyurethane foam

There are regular and professional foam. The first is the one that was universally used (and now too) several years ago by all who decided to repair or replace windows and doors themselves, without the help of specialists. A special screw-on tube was attached to such cans.

And cartridges with mounting foam, the tip of which is designed in such a way as to connect it with a gun, is a professional material. There are no special differences between them, in addition to the auxiliary tool, but ordinary foam is more suitable for minor household repairs - to fix something, connect it together. Professional is more durable and stable, but the method of its application is somewhat more complicated due to the fact that you need to have a gun and be able to use it.

In addition, the foam also varies by season - winter, summer, demi-season - that is, depending on its resistance to weather. You should pay attention to this if outdoor work is ahead. The same with its intended purpose - it is mandatory to indicate on the cartridges for what purposes the material is intended, because insulation, for example, pipelines and the installation of a heavy entrance door, are very different from each other. Be sure to choose the type of foam that you need.

Precautions when using polyurethane foam

Care must be taken during the application of the foam - do not push the valve too hard so that the contents of the canister come out evenly and in small quantities. Polyurethane foam is very poorly scrubbed and can subsequently ruin the coating, so it is better not to allow excess to get on other surfaces. For the same purpose, you can use the following tricks, the so-called life hacks, which "hold" the foam in an upright position, will not let it slip:

- To foam wide slots (more than 1 cm), sprinkle them with water a little;

- For holes wider than 3 cm, use cardboard - divide the area into steps of 10-15 cm and separate them with a thin cardboard, froth; after removing the cardboard there will remain tiny clicks, which are already much easier to fix.

Remember that the mounting foam expands and increases in size as it hardens - for example, ordinary foam can “swell” three times, and a professional subsequently fills the area about 70% more than the original. Therefore, the surplus will be in any case, even if you have distributed the substance very carefully and economically, and you need to remove them with a knife.

If a nuisance occurs and the foreign surface is still damaged, do not try to wash the foam right away. Let it first completely dry and harden, and then carefully scrape it off. The remaining trace can be removed with acetone, and on the varnish, enamel or fabric coating with special detergents, since it can swell from the acetone or lose its color, and the item will be irreparably damaged.

Rules for using a foam gun

Preparatory stage

Shake the can with foam thoroughly (at least 20 times - about 15-30 seconds) and remove the cap. On the gun, turn the adjusting screw clockwise to lock the valve, then attach the container so that it is under the gun. Release the adjusting screw in the opposite direction by half a turn and gently pull the trigger until the foam comes out - this is a sign that the tool is ready, and you can begin to work. With this knob, you will subsequently open and close the content output.

Gun use

The main rule - the cylinder with mounting foam should be on top, above the gun, and in an upright position. Only in this way will the gas push out the contents of the container, otherwise it will just come out and the can can be thrown away for unsuitability. If the gun’s barrel is not enough to penetrate a hard-to-reach place, use an overhead tube, it will serve as a kind of extension cord.

Before work, thoroughly clean the surface, moisten with water (but this is not suitable for winter, since the liquid turns into an ice crust). Attach the gun nozzle to the seam to be sealed and pull the trigger. Do this smoothly and set the desired foam exit speed with the adjusting screw. Do not pull the nozzle out of the foam and try not to make sharp pressure on the valve - this will entail uneven seams, as well as the appearance of voids and tears, which are then almost impossible to level. Fill wide long vertical seams from bottom to top - while you move higher, the foam will dry out from the bottom and create support; from left to right.

Do not forget to shake the can periodically, especially if you work continuously for a long time.

The final stage

Close the gun by turning the screw fully clockwise. Do not disconnect the foam bottle until it runs out - you can still use this material for a month. If you nevertheless removed the bottle, since in the near future you will not need mounting foam, clean the nozzle - removing the foam when it dries is very difficult.

For reuse, shake the gun with foam again, remove dried particles from the tip, loosen the screw and let the foam accumulate; after that you can start work.

Spray Replacement

After emptying the can into the gun you need to insert a new one. To do this, make sure that the former is really empty, and delete it. Close the valve by locking the adjustment screw in the desired position, shake the new cylinder and screw it onto the gun. If the gearbox becomes clogged, clean it with acetone or a cleaner. Loosen the screw and immediately fill the gun with foam.

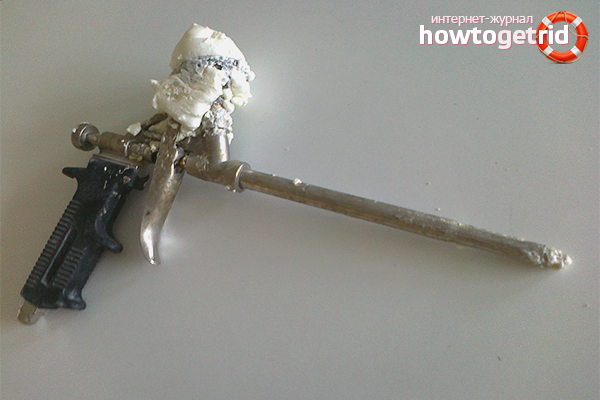

Gun cleaning

In order to clean the gun when all repair work is completed, and there is no need for polyurethane foam, you need to unscrew the container with the substance (most likely, it will have to be thrown away if you do not use it in a couple of weeks, because after this period the foam inside will dry out) . Further, there are two scenarios:

- Purchase a special cleaning agent and screw it in place of the foam bottle, lower the valve and fill the gun. Leave on for 10 minutes, rinse with cleaner again and unscrew the bottle. Wipe the gun with a clean rag.

- This method is suitable for those who completely own their own hands, and are sure that they can not damage the gun. Although if the foam hardens inside tightly, it still can not be removed in a different way. First you need to carefully remove the material adhering to the outside with a knife, then disassemble the gun into parts. Next, look for a long thin wire, stock up with acetone, patience and accuracy. Acetone should be poured onto dried foam and gently pushed with wire - the material will soften, and this will be possible. The muzzle itself is cleaned in the same way - you pour in a little acetone or solvent and, if it’s completely started, pull out the dried foam in pieces, gradually pushing the wire inward so that it comes out from the opposite end.

If you do everything right, the gun will serve you for many years. With regular use, it is recommended to clean it every 2-3 months, regardless of the frequency of change of foam cylinders.

Video: how to use the foam gun

Submit