The content of the article

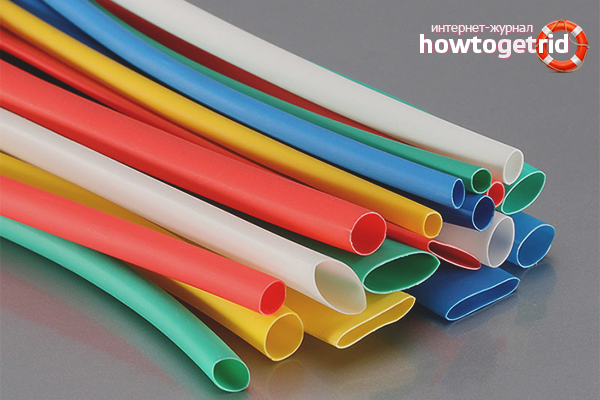

A heat shrink tube is a device that can change diameter, shrink under the influence of high temperatures. In the process of shrinkage, it will cover the object placed in it, and will provide protection: insulation and from mechanical damage. The scope of the tubes is radio electronics, automotive, used as a wire insulator, to protect metal pipes from corrosion, as well as for antenna equipment.

Key statements

In simple terms, heat-shrink tubing (HERE) is a replacement for the standard blue electrical tape. The only thing that they can not be used in areas with ornate bends and where there is a different thickness along the "follow".

Their main advantage is the ability to shrink when heated, it provides the necessary insulation and mechanical protection. The cost of the tubes is relatively low, the usability is provided by different colors, including the most common for cables - red, blue, green, yellow, striped. Using them, you can not only isolate, but also mark the wires to facilitate future work with them.

I would like to dwell on the labeling in more detail, since this is one of the important areas of use of HERE. They are widely used, if necessary, to mark three-phase electrical circuits. They use red, yellow and green colors. By marking also wires that correspond to a certain phase, the operation process can be facilitated. The standard grounding option is yellow-green banding.

Material characteristics

Before using HERE, they need to be selected correctly, and for this to know the main characteristics. These include:

- Shrink ability - this ratio varies from 1: 2 to 1: 6.

- Adhesive layer.

- The composition of the tube - it can be PVC, polyolefin, elastomer, fluorine polymer.

- Color - one-color, combined.

And also resistance to such influences - temperature, chemical exposure, light stabilization, resistance to oil products.

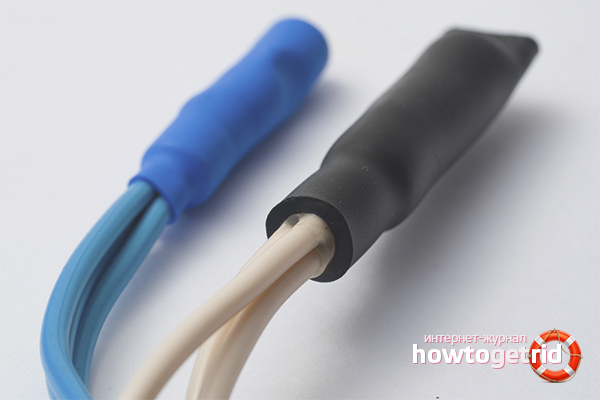

There is also a separation according to the strength of the tube walls, according to this indicator HERE are thick, medium and thin-walled. The first two species are combined into one group and are characterized by a wall thickness of 1.5-4.5 mm, which it will become as a result of shrinkage. Indicators in this case vary from 2: 1 to 6: 1. It is in them that there is an adhesive inner layer.

Thin-walled can be transparent or colored, with a wall thickness of up to 1 mm after shrinkage, the narrowing coefficient is from 2: 1 to 4: 1. Used as insulators and as markers. They often have special characteristics, among them:

- Self-extinguishing.

- Lack of halogen emissions during fire.

- Heat resistance.

- Low temperature shrink.

- Improved UV resistance.

- Resistance to mechanical and chemical influences.

Important recommendations when using HERE

- Designating the size of the tube, manufacturers indicate two numbers through a fraction: one is the diameter before shrinkage, the second after. Additional markings may indicate the color and length of the cut.

- When you choose HERE, it is important to consider that its diameter should be larger than the product for which it will be used. For shrinkage to occur correctly, its diameter after shrinkage should be slightly smaller than the diameter of the product on which it is mounted.

- Before using HERE, you need to inspect it for damage and burrs. If there are scratches or barbs, it is better to refuse the use of such tubes.

- If you plan to use HERE with an adhesive layer, then first the surface on which they will be seated must be cleaned and degreased. To avoid damage to the tube, there should be no places on the product that could be potentially hazardous for HERE. If there are sharp edges, they need to be sanded and leveled.

Terms of Use HERE

First you need to prepare the tools. For this, any sources that give the necessary heat flow are suitable. The minimum temperature should be +70 degrees. Necessary indicators are indicated when marking. It depends on the type of tube: for thick-walled, the temperature should be higher, for thin-walled - lower. If you plan to use a building hair dryer, then the requirements for it are the identification of the required temperature. If you use gas burners, it is important that they have a soft yellow flame. Options for use as a heat source can be matches, lighters.

Shrink Technique:

- Surface preparation, which includes degreasing, cleaning and heating. To do this, depending on the material, sandpaper or a cloth soaked with solvent can be used.

- The choice of the tube in accordance with the requirements, its heating, which is especially important for thick-walled tubes. It needs to be warmed up without sitting on the place of “permanent residence” and not to the maximum temperature, but by half, that is, if the temperature of complete shrinkage is 120 degrees, then it needs to be warmed up to 60.

- Next, the tube is mounted on an insulated object, a surface. On the heating device set the required temperature.

- Shrinkage should start from the middle. After uniform sitting in the center, move to the right and left.

- It needs to be heated evenly, moving the heat source along it, this will not allow local overheating, and therefore, damage to HERE.

- If there is glue on the inner surface, then it should leak out as a result of shrinkage. After shrinkage, the object must be left alone until it cools completely.

The use of HERE is a modern and convenient solution. To feel all the advantages of this insulator, you need to use it correctly. We tried to explain in as much detail as possible everything you need to know for the successful application of HERE.

Video: how to use shrink tubing

Submit