The content of the article

Glass cutting can be attributed to jewelry. Indeed, real experts can make a piece of this material a real masterpiece. However, this will require a fairly large amount of experience. At the same time, many cannot simply cut glass in half, as they don’t know the basics of cutting glass.

We are not saying that we will make you a sculptor with a glass cutter instead of a cutter. However, you will learn how to make glass countertops and other similar things.

Glass Cutter Selection

Any training begins with an introductory part. There are no exceptions in our case. Before we get down to business, you need to familiarize yourself with many equally important aspects. One of them is the choice of glass cutter. There are 3 main types of these tools:

- Glass cutter with a cutting tool made of natural diamond. This tool is the most popular. It has a tip that can cut glass up to 10 mm thick. In this case, the cuts are always obtained perfectly smooth and without various defects, of course, if used correctly.

- Roller cutting tool. His working tool is made in the form of a roller. Unlike the first option, instead of diamond, a special alloy of solid metals is used here, which is often tungsten and cobalt.

- Oil glass cutters are not much different from roller counterparts. And to be more precise, there is only one difference. It consists in the fact that during cutting, a special oil lubricant is supplied to the cutting tool. It will not accelerate the cutting process, however, this is not the advantage of the tool. Continuous oil supply will extend the life of the roller mechanism.

Returning to the first view, it is worth noting that the tool is not cheap. However, there are analogues that cost less. The difference is that instead of a real diamond, its artificial counterpart is used. It is worth noting that in terms of cutting quality it is not much inferior to the original, but it is effective in cutting glass up to 5 mm thick.

Preparation of glass and workplace

Before cutting, the glass must be prepared. If new material is used, wiping with a dry cloth is sufficient. But glass that has already been used in everyday life should be treated with special detergents, and then degreased with kerosene. In conclusion, it is necessary to dry it thoroughly.

As for the workplace, there are few requirements for its preparation, or rather, there are none at all. It is enough just to have a flat free table and a container for waste glass.

Diamond Cutting

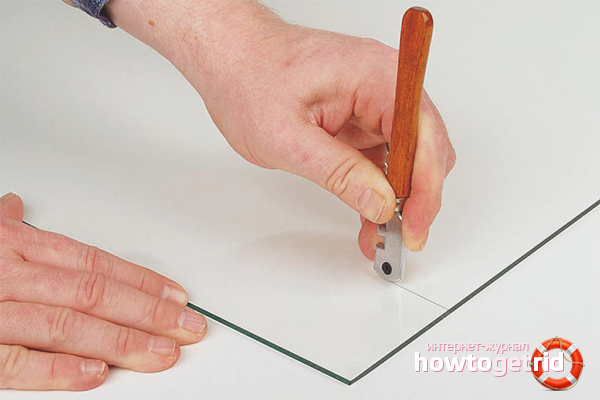

Diamond glass cutter is not only reliable, but also convenient. The principle of operation is quite easy. The tool is held by the handle like a pencil. Next, an incision is made on the glass. In order not to screw up, it is recommended to use a ruler or a pre-cut template.

You can also use one more trick when marking up. It will suit if you need to make a direct incision. So, the essence is as follows. A straight line is marked on the table with a marker. Glass should also be labeled. But to draw a thick line is useless. It is enough to make notes at the edges of the material, between which the cut will be made. After this, the labels should be set so that the line on the table connects them.

Back to the cutting process. The essence is clear, but there are some nuances that should be considered.

- Diamond glass cutter should be kept at an angle. At the beginning of the section it was said that it looked like a pencil. So “draw” is also necessary as a pencil.

- Do not press hard on the tool, otherwise the cut line will be uneven and full of chips.

- Repeated cutting along the line already carried out by the glass cutter is a taboo. Do not ask too many questions, just try to do it right the first time. If the fault has already failed, you should shift a little and repeat the procedure.

- Make an incision quickly. A meter should take about 2-3 seconds.

What to do after the cut line has been drawn? It is necessary to move the glass to the edge of the table so that its unnecessary part is a canopy. Further along the entire line of the incision, one simple procedure should be carried out. From below, on the back of the cut you need to lightly tap on the glass. If everything is done correctly, the unnecessary part will easily disappear. The main thing - do not forget to substitute a container under it or hold it by hand.

Glass Cutter Cutting

Before figuring out how to cut glass with a roller tool, it should be recalled that it is not as durable as diamond glass cutter. The roller regularly cuts the first 300 meters. After this, replace the workpiece.

Now you can get down to business. The first step is to mark up. You can do this, just like in the first way, so there is no point in re-describing these methods. The principle of operation as a whole is also no different. However, there are still some differences in the intricacies of the process.

- Unlike diamond glass cutter, which should be held at an angle, in this case, the tool should be perpendicular to the plane of the glass.

- The roller glass cutter should be pressed harder, otherwise the glass will not cut through.

Next, we do the same thing as in the previous section.

Cutting with oil glass cutter

For this cutting method, it was possible not to create a separate section in the article. After all, the method is no different from the above, only the roller is lubricated with oil, due to which the cutting process is facilitated, and the life of the working part is increased.

How to cut a circle

How to cut the glass in half, we have already figured out. But it is also worth paying attention to one important issue. Namely: how to cut a circle out of glass? In this case, you can use two options:

- Apply a round solid pattern to the glass;

- Use a special compass.

The second option is more reliable and simple. Therefore, the use of round patterns is recommended only if there is no way to get compasses.

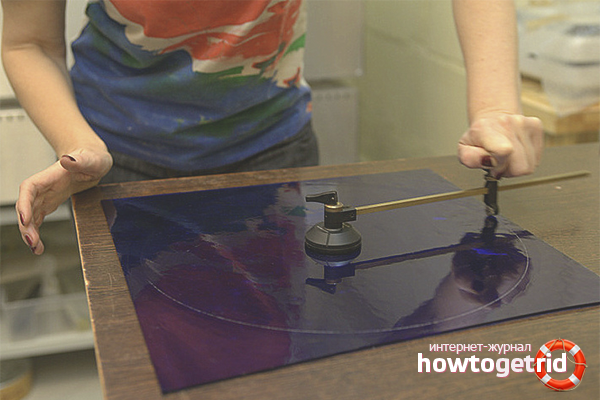

Let's see what constitutes such a compass. In fact, this is a fairly simple design, which consists of the following components:

- Sucker;

- Glass cutter;

- Tripod.

How to use the compass is intuitive. The suction cup is attached to the glass, and the glass cutter is exposed on a tripod with the necessary measurements. After that, a quick but smooth cut is made on the glass. Then the circuit should be slightly beaten off with a hammer. Done.

Useful Tips

- Working with sharp glass is quite dangerous. Therefore, you should stock up on gloves and special glasses.

- Glass cutters are more functional than it might seem. Almost every model has a recess, which allows you to break off small pieces of glass.

It is worth repeating. The above tips and tricks will not make you a glass cutting pro. However, following them, you will immediately understand the basics of this matter and be able to cut simple shapes.

Video: how to cut glass at home

Submit